Graph Writing # 54 - Process by which bricks are manufactured for the building industry

- Details

- Last Updated: Monday, 20 July 2020 16:15

- Written by IELTS Mentor

- Hits: 560514

IELTS Academic Writing Task 1/ Graph Writing - Flow Chart/ Process Diagram:

» You should spend about 20 minutes on this task.

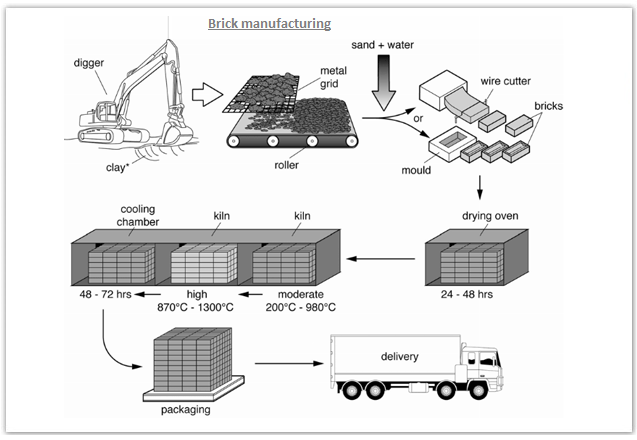

The diagram below shows the process by which bricks are manufactured for the building industry.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

» Write at least 150 words.

Sample Answer 1:

The given diagram shows different stages of brick manufacturing for the building industries. Generally speaking, brick production involves 7 steps, starting from the digging stages and ending at the delivery stage.

As is given in the graph, the first step of brick manufacturing is digging the clay with a large digger. This clay is then filtered and processed in a roller machine and then mixed with sand and water. In the third stage, the mixture is either kept in a mould or cut in a wire cutter to make the raw shape of the bricks. In the next step, the shaped raw bricks are dried for 24 to 48 hours in a drying oven. After that, the dried raw bricks are kept in a kiln, both in moderate and high temperature, up to 1300 degree centigrade and then placed in a cooling chamber for about 48 to 72 hours. This process makes the brick to be packed and delivered in the final two steps. The delivery process is the final process of brick manufacturing and as it is noted, brick making is a moderately complex process that requires some predefined works to make it usable.

(Approximately 195 words)

Model Answer 2:

The diagram gives information about the manufacturing process of construction bricks. Overall, brick manufacturing requires some controlled stages and complex equipment.

To begin with, the clay is collected by a digger machine and then the clay is passed through a metal grid to grind them. The smashed clays are transported to a roller and sand and water are mixed with this. The mixture later either moves through a brick cutter, which shape of bricks, or is placed into a mould in which the shape of a brick is formed. Afterwards, these brick-shaped parts are put into a drying oven and stay there for 24 to 48 hours. Next, they are transferred to the first kiln for heating, whose temperature is moderate, 200 to 980 C. After this, they are heated in the second kiln under the high temperature from 870-1300C. Subsequently, in a cooling chamber, they are cooled for two to three days before they are packaged and delivered to the construction sites.

To summarise, the whole process consists of generally seven steps during which the raw material is dried, heated, cooled and packaged.

[Written by Thomas]

Sample Answer 3:

The diagram illustrates the brick manufacturing process in an orderly manner starting from the digging of clay. As is seen in the given illustration, brick manufacturing is a complex process and involves 7 stages until they are ready to be sold in the market.

The process is initiated by digging clay with the help of a heavy machinery digger. This clay is then refined through the metal grid which throws the refined clay on the rollers. Sand and water are mixed and this mixture is either moulded or cut using a wire cutter to give the bricks a raw shape. These bricks are put in a drying oven for one to two days. The dried bricks are then passed to kilns with moderate (200 to 980 degree C) and high temperature (870 to 1300 degree C) and finally placed in a cooling chamber for 48-72 hours. After cooling down the bricks, they are placed on a pallet for packaging and to be loaded on a lorry for delivery.

In conclusion, the process of manufacturing bricks is a complex process which passes through several stages before the bricks are ready to be used.

(Written by Sami Satti)

First, the clay is excavated using a digger and passed through a metal grid to remove debris. It is then mixed with sand and water to create a uniform paste. This paste is shaped either by using moulds or by passing it through a wire cutter to produce bricks of the desired size.

Once shaped, the bricks are dried in a drying oven for 24 to 48 hours. They are then fired in several phases: first at moderate temperatures (200°C to 980°C), followed by high temperatures (870°C to 1300°C) in kilns. After firing, the bricks are left to cool for 48 to 72 hours.

Finally, the cooled bricks are packaged and transported by truck to their final destination. This process ensures that the bricks are strong and ready for use in construction.

Overall, the process comprises 4 main steps: exploiting clays, moulding, baking and finally distributing.

First, a big digger machine collects the raw clay, which is then separated from any pebbles or strange substances using metal grids. Next, clay is mixed with sand and water in an appropriate proportion to create a mixture for moulding. Bricks can be shaped in two ways: singular by moulds or multiple by wire cutter lines. Once all the raw bricks are shaped, they need to be set in the drying oven for 24 to 48 hours before baking. In this stage, raw bricks are heated at two temperature levels: the first is from 200°C to 980°C, and the second is from 870°C to 1300°C. After that, baked bricks are cooled in the chamber for 2-3 days so that they can be packaged for shipping. Finally, new bricks are distributed to construction sites where they are needed and ready to use for building.

Once the sticky earth is collected and separated from the soil, the clay is moved immediately to the metal grid which turns it into brick-manufacturing raw material. It is sent through the roller to be mixed later with sand and water and dropped to two different brick makers which are the wire cutter and the mould.

Once ready, both two brick types are transferred to the drying oven which takes between 24 to 48 hours to be completed so that it can be sent to the kiln steps. Firstly, the clay is fired in a moderate kiln with a temperature between 200°C and 980°C then it goes automatically to a higher temperature kiln with over than 870°C to a maximum of 1300°C. Then finally, they are transferred to the cooling chamber which takes between 48 and 72 hours to end the operation. After being packaged the bricks are ready to be placed in transport then delivered to building industries.

Overall, it can be seen that it requires a sophisticated process for manufacturing bricks, which consists of 7 stages, starting with the digging of clay and ending with the packaging and delivery. Moreover, several instruments, such as roller, drying oven, kiln and cooling chamber are needed for this.

The process begins when the clay is dug by a digger and is passed through a metal grid, which converts it into finer fragments. When this stage is completed, the fragments are carried by a roller before adding water and sand to it. Afterwards, this mixture can be transformed into bricks either by using a wire cutter or by putting into a mould to give this the shape of bricks.

The next stage starts by transferring the delicate and fragile bricks into drying oven where it is dried for 24 to 48 hours. This is followed by shifting of the bricks to moderate temperature kiln (200-980°C) and high-temperature kiln (870-1300°C), respectively. After completion of subjecting the bricks to a high-temperature kiln, they undergo cooling for 48-72 hours in the cooling chamber, following which they are packaged. The last stage is when they are delivered by a truck for further construction purposes.

Report